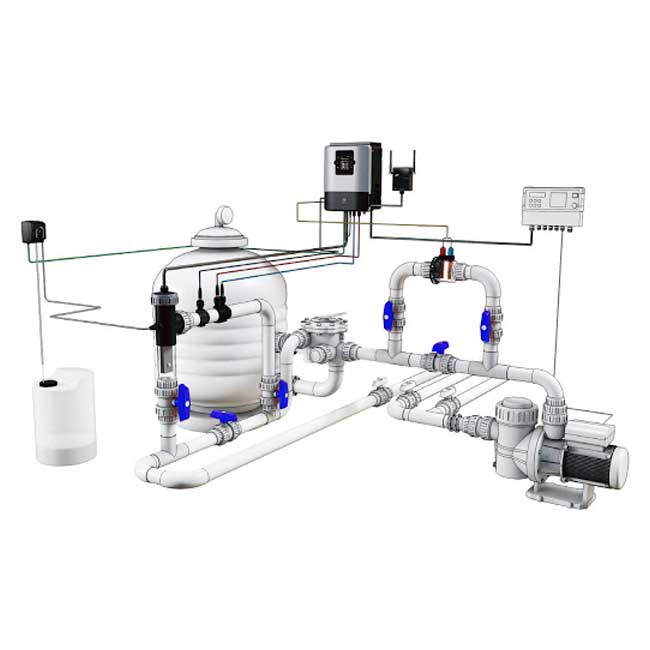

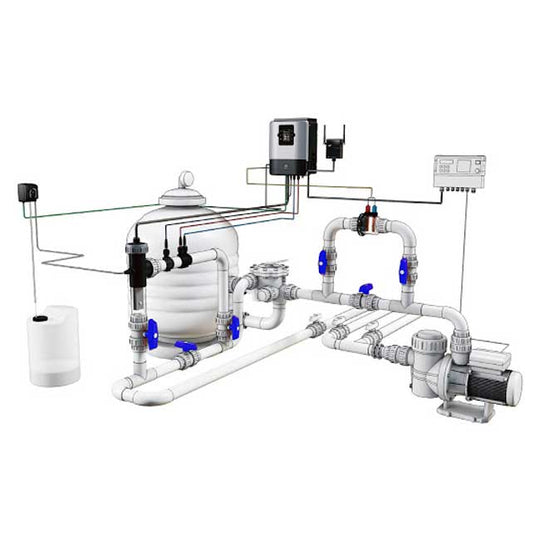

Oxilife from Sugar Valley is a low salinity Hydrolysis and Electrolysis set that provides maximum cleaning with minimal chlorine production. Its action provides perfect disinfection of water with a minimum of salt.

For what type of pools?

- They are easily installed in new or existing pools. It adapts to all types of pools and coatings.

- Three versions:

- Oxilife OX 0 - up to 20m3**

- Oxilife OX 1 - up to 60m3**

- Oxilife OX 2 - up to 120m3**

Working principle:

LOW SALINITY HYDROLYSIS AND/OR ELECTROLYSIS

Water is made up of 2 parts hydrogen and 1 part oxygen (H2O). Hydrolysis means, etymologically, decomposition by water. Hydrolysis is a process to generate hydrogen and oxygen using electricity and water.

When electric current passes through water, the chemical bond is broken, negative charges or oxygen ions migrate to the positive electrode (anode). Positively charged hydrogen ions are attracted to the negative electrode (cathode). The decomposition that occurs is the following:

Electrical energy +2 H2O --> 2 H2 + O2

This results in an extra negative element, since in the combination the number of electrons exceeds the number of protons by 1. It is now a single negatively charged hydroxide, or hydroxyl ion (OH-).

In HYDROLYSIS there are numerous secondary chemical reactions, which also produce ionic species with oxidizing and disinfecting power, such as ozone (O3), monatomic oxygen (O1) and hydrogen peroxide (H2O2).

The electronic circuit of our electronic box transforms current (220 V, 50 Hz) into low voltage, high amperage direct current. This current is supplied to titanium electrodes activated with noble metals placed in the water recirculation in a support specially designed for this purpose.

If we incorporate a very small amount of salt in this treatment (between 1 and 2g salt per liter of water), either due to lack of conductivity or because we want to generate a tangible residual, we will ensure that the same system also generates a chlorine residual per saline electrolysis at low concentration. The products decompose, act and are regenerated again. The residual disinfectant generated by electrolysis does not harm the eyes, skin or health of the bather. Without caring about the fact that we run out of salt in the water, since the system would continue disinfecting in HYDROLYSIS mode. The chlorine generated destroys the organic matter and pathogens present in the water, transforming it back into sodium chloride (common salt).

Features:

- Real-time water quality control

- View and control: pH of the water, redox or free chlorine, conductivity and salinity of the water, temperature of your heat exchanger pool)

- Control filtration periods

- Timed Automatic Function (up to 3 periods/day)

- MANUAL on and off

- Timed Automatic Function (up to 3 periods/day)

- MANUAL on and off

- Up to 4 additional auxiliary controls

- Filtration control

- Automatic (or timed) MODE

- Manual MODE

- Smart MODE*

- Heating MODE*

- Smart MODE*

(*) Modes only available when the equipment incorporates a Temperature probe

(**) The published prices correspond to the non-touch digital screen. There are 2 screen models available, digital and digital touch. The two screen variants have different prices.

Documentation:

Do you need a spare part?

Click here and tell us the spare part you need.